Intumescent Coatings (FLAMASTIC)

As is known, in case of fire, the bearing structures, a because of their thermal conductivity, they can quickly reach high temperatures up to cause them to collapse. Especially in the case of metal structures, fire prevention rules,

set the maximum temperature limit in 350 ° C (in the points of maximum thermal stress). And this for the structures without overloads. However in case of fire, in relation to the quantity and calorific value unitary of materials, the critical temperature can be achieved very quickly. For this the rules of fire prevention prescribe passive protection structures through intumescent coatings, which they delay the achievement of the critical temperature. Refrasud International Srl has developed products and cycles of fire treatment for:

- Metal structures

- Wooden structures

- Electric cables

- Concrete structures and / or Plasterwork

By the term intumescent coating, we mean a coating with a thickness varying from some a hundred microns to a few millimeters, applied according to the classic and usual paint echniques (brush, roller, spray). An intumescent coating must have the characteristic of swelling, below the action of heat, its original thickness, forming an insulating foam whose job is to prevent the transfer of heat from the source to the support on which it is applied. The purpose of the coating is therefore that of keeping the support, for some time, at temperatures such that the deformation process or collapse (iron structures) is slowed down and hindered, thus actively contributing to the stability of the structure in case of fire. This also simplifies the design of the load-bearing metal structures since, with protection light, uniformly distributed, profiles and shapes of any kind become feasible; contrarily to what happened in the past, when the protection consisted of complex conglomerates, coatings orcement-based infills. Under the effect of heat, the original layer of the film swells into a foam whose thickness is proportionalthe quantity of material applied; the insulating power of the foam, its stability and durability, they depend exclusively on the materials chosen for the formulation of the paint.

As part of this problem, Refrasud International Srl has developed highly products specialists such as INTUCARB 099 / A (water-soluble intumescent paints) and the related INPRIMER 099 / A primer (one-component water-based primer, pigmented with anticorrosive pigment based on phosphate ofzinc, selected resins and fillers), which, by decomposing in contact with fire, generate a barrier insulation that resists heat. In all our products there is the patented chemical conditioner Carbonxide-M1which, in the case of intumescent products, allows the formation of a foam characterized by one microporous structure with lower thermal conductivity coefficient (λ) and higher specific heat compared to similar products on the market. This peculiarity (lower thermal conductivity and greater specific heat), allows a substantial decrease in thermal diffusivity (i.e. acquisition and disposal of heat), which translates into a significant improvement in resistance to fire, for the same quantity of material applied compared to traditional products existing on the market.

OPERATIONAL PRACTICE FOR THE APPLICATION OF INTUCARB 099 / A ON METAL STRUCTURES

- Thoroughly clean the substrate to remove all traces of dust, grease, oil, oxidations.

- If necessary, sandblast to the minimum Sa 2 degree (SSPC-SP6).

- Apply where necessary a preventive coat of INPRIMER 099 / A anti-rust on carpentries, on wooden supports one coat of INTUCARB 099 / A diluted 20% with water. On hollow gangways proceed directly to the application of INTUCARB 0990/A.

- Shake the product well before use, preferably with a low speed drill.

- To spray the product on large surfaces use quick-change nozzles type Larius 35.40, while for narrow surfaces, max. 100 mm, (e.g. carpentry) use Larius 35.25 type nozzles.

- Do not exceed a pressure of 2 – 2.5 atm during application.

- Take care to position the spray nozzle at least 40 – 50 cm from the support.

- Use a Nova 45: 1 pump to spray the product, taking care to wash it every 3 – 4 cans of product applied

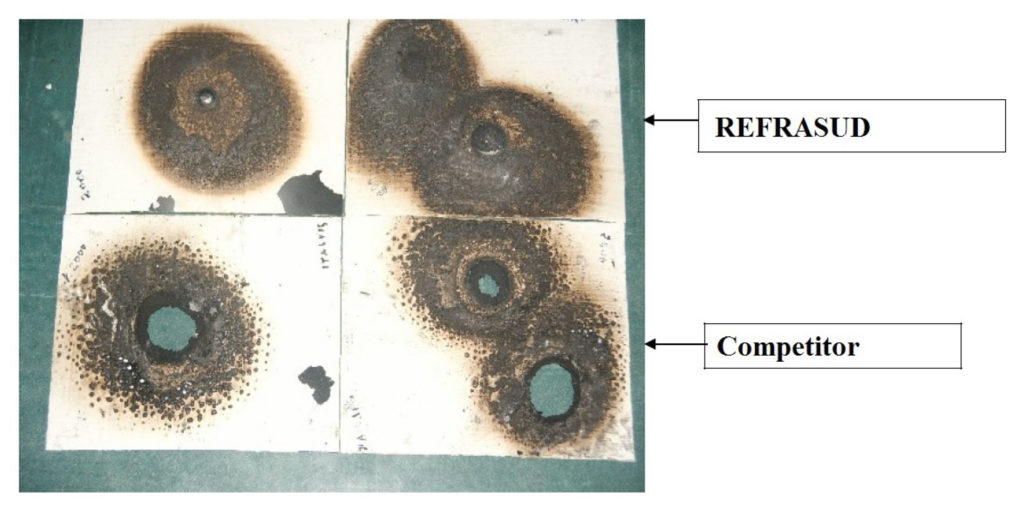

ThyssenKrupp Acciai Speciali Terni - TEST REPORT INTUMESCENT PAINTS

Test Data

- heat source: oxyacetylene torch

- distance: 15 cm Combustibile combustible material used: rubber

- amount of paint sprinkled: 2 kg per square meter

- fire action time 3.5 minutes and 4.5 minutes

- resulting thickness in the dry: Refrasud 1000-1100 microns; (*) 900-1000 micron

TEST RESULT

The level of reaction and fire resistance is clearly evident on the photos. In conclusion we can consider the behavior of Refrasud paint better than the competitor (*)